STABLE ELECTRICITY SUPPLIERS

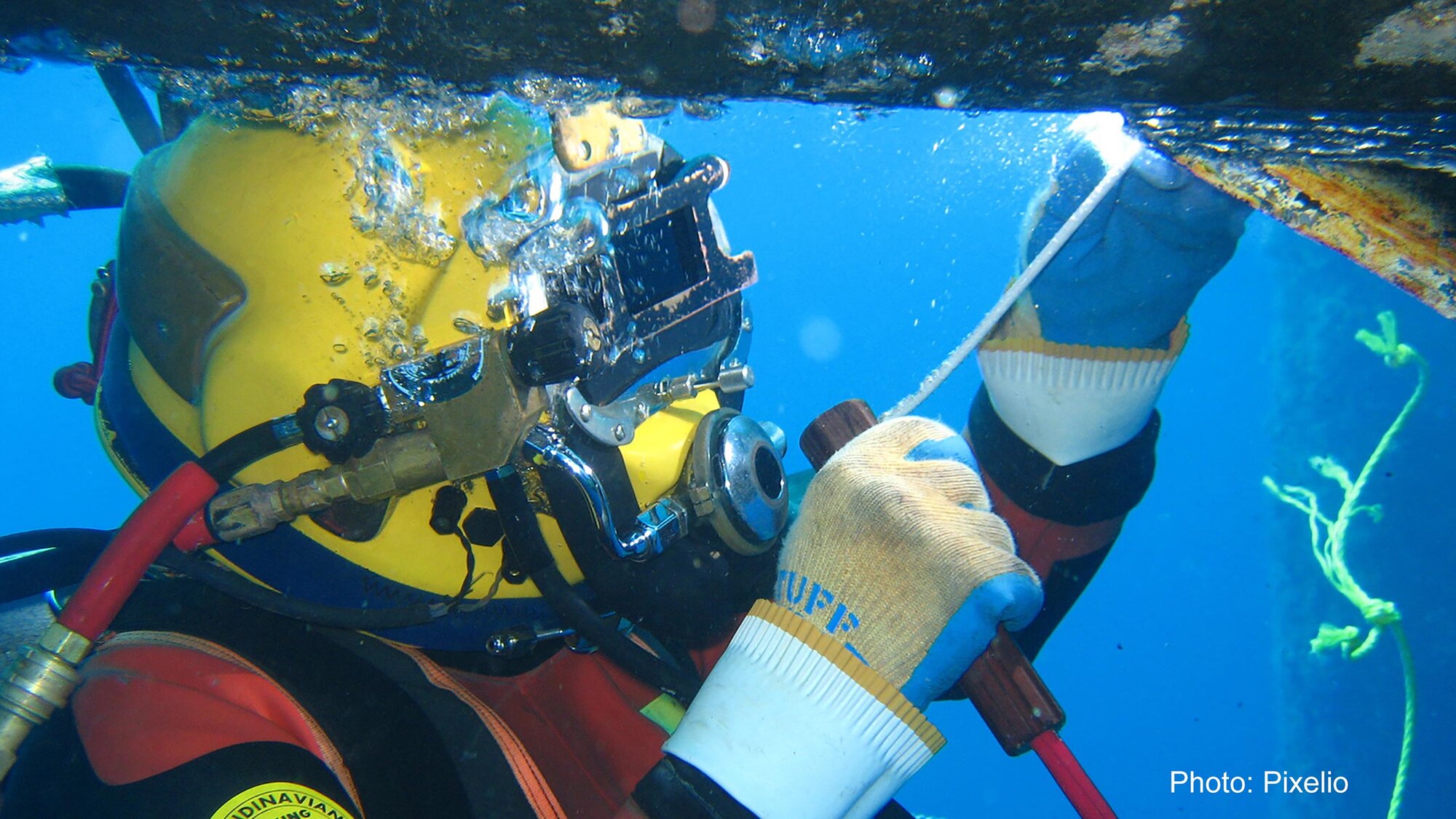

Offshore wind turbines are playing a major role in the energy transition. More and more of these gigantic wind turbine towers are made of high-strength steel components whose thinner wall thicknesses make them significantly lighter than ones made of conventional steels. With Messer’s support, several universities and institutes are conducting research into reliable high-speed welding methods for joining those high-strength steels. One such solution is laser hybrid welding. It combines the advantages of laser welding with those of arc welding, resulting in a concentrated application of heat while affording greater dimensional tolerances. Unlike the towers, the structural foundations of offshore wind turbines are still made of low-allow steels. If necessary, they can be repaired underwater right there on site. The only way to make such repairs is with arc welding, which also uses welding gases from Messer.